|

|

Most garden railroad buildings sit out on dirt or gravel in different locations around the railroad. I wanted mine to have a better appearance. I also wanted them to stay put in strong winds. I have made a few wood buildings and they would blow off the hill and get damaged. Even in the 1880's carpenters attempted to make some kind of a foundation. I decided to make concrete bases to which I could anchor the buildings.

|

|

|

After I cast the concert base I drilled a few holes and used plastic anchors, screws and some wooden clamps to attach them to the base. The crack in this base came from picking it up before it had fully cured. You have to wait at least 2 days before trying to move it.

|

|

I made an adjustable form so I could cast any size base. It is made from pine 1 by 4's cut exactly 2" for the height.

|

|

I used aluminum angle for the corner braces. I screwed them flush to one end and used a C clamp for adjustment. I cast on top of a piece of plywood covered with some kind of plastic to keep the water from warping the plywood. I also oiled up the sides of the forms so the concrete would not stick to the wood. I used motor oil and put it on with a paper towel. A good coating is required. I use quikrete 5000. I tried their fast setting concrete but it was hard to work with. You can add coloring to get different effects. Experiment, have fun.

|

|

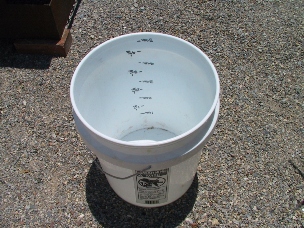

At first the big issue was all the wasted concrete. It was hard to predict just how much concrete to use. At first I tried weighing the concrete but that was to much of a hassle and not accurate. I made up a chart to help me determine just the right amount. I took a 5 gallon bucket and marked it off in half gallons. I could determine how many gallons I needed and add a little extra for error. Now I waste very little concrete and make far less of a mess. The chart is provided as a Word document. Weight of concrete for a given size form.doc An example is shown below

|

Thick

|

Wide

|

Long

|

cub. inch

|

cub. foot

|

Lbs/CuFt

|

Pounds

|

Gallons

|

|

2

|

10

|

16

|

320

|

0.185

|

135

|

25

|

1.4

|

|

|

I mix the concrete in my wheel barrow following the manufacture's instructions. I put it in the form and work it well. Make sure you float it and scrape the sides of the forms to eliminate any air pockets. Do not pull the forms away for a few days or you will not get a good edge.

|

|

On this base I allowed a little extra room for the platform.

|

|

This base makes up the floor for the sawmill.

If I get some erosion it is a easy fix.

|

|

I glued small tiles to the sides of this base to simulate a cut stone foundation.

I used exterior quality tile adhesive.

|

|

I used contact cement to glue small wood strips to the outside of this base. This sawmill is made up of several bases. This leaves a seam but you have to keep the bases manageable in size and weight.

|

|

I pulled the forms away to quick here and got a divot on the edge.

|

|

This is a very small base.

The concrete bases improve the appearance of your buildings and give you a method of anchoring them down. Try it, but remember to give the concrete a couple days to cure. I made two sets of forms for when I am in a hurry.

I hope you find this information useful. If you have any questions contact me at NMGRR@comcast.net

|